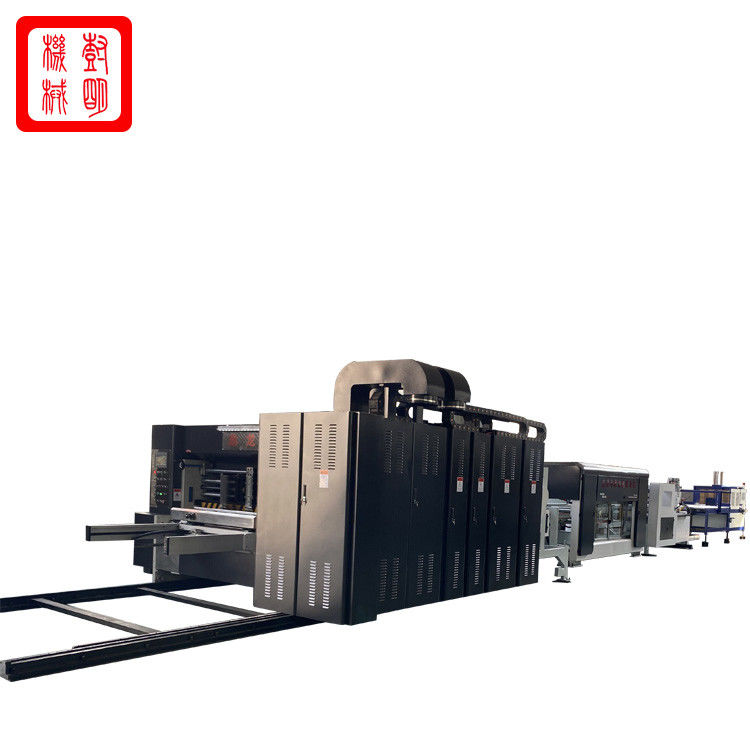

Corrugated box slotting die cutter Cardboard Printer Line

cardboard printing slotter die cutter machine Cardboard Printer Line

full automatic carton making Cardboard Printer Line

Specification/

Max feeding size(mm) |

1800/2000*800>

Cardboard Printer Line

|

1800/2200*1000

Cardboard Printer Line

|

2500*1200/1400/1600

Cardboard Printer Line

|

2800*1200/1400/1600

Cardboard Printer Line

|

3200*1600

Cardboard Printer Line

|

| Max speed pcs/min) |

250 |

200 |

160/150/120 |

150/140/120 |

120 |

| Min feeding size(mm) |

650*270 |

650*270 |

650*330/350/400 |

650*330/350/400 |

650*400 |

| Skip feeding size(mm) |

1800/2000*1000 |

1800/2200*1200 |

2500*1400/1600/1800 |

2800*1400/1600/1800 |

3200*1800 |

| =Cardboard Thickness= |

2-10 |

2-10 |

2-12 |

2-12 |

2-12 |

| Max. printing size(mm) |

1750/1950*750 |

1750/2150*950 |

2450*1180/1330/1580 |

2750*1180/1330/1580 |

3150*1580 |

| Print plate depth (mm) |

7.2 |

Min slot

(mm) |

Positive cut |

120*120*120*120 |

120*120*120*120 |

140*140*140*140 |

140*140*140*140 |

140*140*140*140 |

| Reverse cut |

200*80*200*80 |

200*80*200*80 |

240*70*240*70 |

240*70*240*70 |

240*70*240*70 |

| Max die cutter area(mm) |

1700/1900*750

Cardboard Printer Line

|

1700/2100*930

Cardboard Printer Line

|

2400*1150/1310/1550

Cardboard Printer Line

|

2700*1150/1310/1550

Cardboard Printer Line

|

3100*1550

Cardboard Printer Line

|

Use for corrugated cardboard box making Cardboard Printer Line

Use for pizza fruit vegetables ect boxes making Cardboard Printer Line

Use for paperboard Cardboard Printer Line

►Feeding roll is made of two-layer rubber,inner layer is soft and outer layer is hard,this makes inner layer more flexible and surface more

wear-resistant,and reduce the flute damage of the Cardboard Printer Line;

►Dust remove system with brush and segmented vacuum sheets cleaner; Self-locked system adopts for adjusting feeding rolls gap,motorized

and PLC control of feeder side guides Cardboard Printer Line;

►Motorized backstop forward /backward and up/down position for easy and quick adjustment Cardboard Printer Line;

►Main motor is protected from starting up when units are not fully closed and locked Cardboard Printer Line.

►Mounting roller with left and right both of side locking device,let the mounting position more accurately Cardboard Printer Line Cardboard Printer Line.

►Pneumatic clutch is adopted on the anilox roll to:

(1)Make the roll run at the same speed as the main motor when the unit is printing Cardboard Printer Line;

(2)Make the roll stop when the unit is not printing Cardboard Printer Line;

(3)Reduce the possibility of damage to the rubber roll and the anilox roll for inproper operation Cardboard Printer Line;

(4)Allow units which are not in use to be washed up while running Cardboard Printer Line.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!