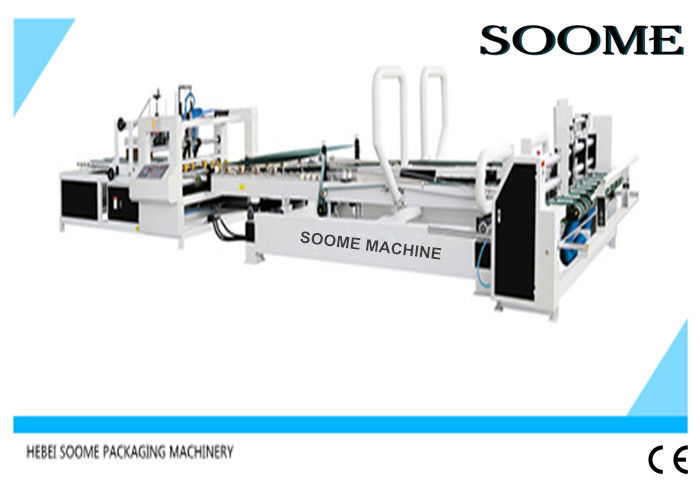

High Speed Auto Folder Gluer Machine Circulation For Small Express Box

I. General introduction

Automatic folder gluer can finish 10000pcs cartons per hour with 4workers. Speed can be max. 400pcs/min. which can solve the problem of more workers, low production efficiency and difficult management.

I. Machine composition and principle

1. The auto folder gluer is composed of Paper feeding and gluing part, Creasing and folding part, Correcting counting and outputting part, totally 3 parts.

2. This machine adopts high quality rolled steel with welding and elaborate processing to assemble well.

3. Adopt belt type auto suction feeding, fast and exact.

4. Automatic glue supplying, glue circulation, will not stop glue offering, no need offer glue by manual, save time and labor.

5. Stainless steel gluing wheel, anti-corrosion, anti-abrasion, glue averagely, save glue, the needed glue volume is about one third of manual gluing volume.

6. The folding part equipped with several groups of adjustable creaser, make sure the carton folding more smoothly and gluing more beautiful and exactly.

7. Counting part with piling and correcting, output steadily, no error, simple operation of digital control, can input sizes without stop of machine.

8. Equipped with fault detect device, when the machine break down, will stop automatically, can reduce the waste of paper.

9. Can store 1000 orders, change orders both manually and automatically. After recalling the order, it will change the order automatically within several minutes. Decrease the order changing time, improve the working efficiency.

II. Main parts

1. Electrics

| Items |

Brand |

| Touch screen |

MCGS |

| PLC( Master control) |

Panasonic |

| Power supply |

MeanWell |

| Frequency inverter |

Delta |

| Buttons |

Schneider |

| A.C. contactor |

Siemens |

| Intermediate relay |

Omron |

| Travel switch |

CHINT |

| Breaker |

CHINT |

| Electromagnetic clutch |

Zhejiang brand |

Remark: the above electrics can be chosen as per customer need.

2. Bearings

Bearings mainly adopt HRB brand, also have Zhejiang Wanxiang brand, Shanghai Xinling. Optional: can choose Japanese NSK, Germany FAG brand if you need.

3. Belt

Adopt Germany Siklin mainly, combined with less qty from Shanghai. Suppliers are Shenzhen Sibeck, Tianjin Liyangze, Germany Senli.

III. Design speed: 140m/min. Machine dimensions: 13500x3000x1700mm. Weight: about 5tons.

IV. Power voltage: AC220V / 380V (as per different country) 60HZ Power: 9.5kw

1. Variable frequency motor: 4kw 1set, 2.2kw 1set; Yongshun brand

2. Turbine reducer: 0.18kw 3sets ; Shandong Senda brand

3. Gear reducer: 0.1kw 3sets, 0.2kw 2sets; Taiwan Shengbang brand

4. Fan: 3kw 1set

V. This machine can process 3layers, 5layer (2-9mm) corrugated board. Range is : Max. Paper size 1000x2000mm, Min. Board size 170x420mm, 130mm ≤ carton length ≤ 880mm, 80mm ≤ carton width ≤ 880mm, 70mm ≤ carton height ≤ 1000mm.

Automatic folder gluer, composed with 3parts: Paper feeding and gluing part, Creasing and folding part, Correcting counting and outputting part. Variable frequency control, easy to operate. Automatic folding, auto counting, auto stacking and outputting. Average speed about 150pcs/min. Auto feeder part need 1worker, outputting part need 3workers ( when paper size ≤ 600x1200mm), can finish 12000pcs cartons/h. Auto feeder part 2workers, outputting part 3workers (when paper size ≤ 1000x2300mm), can finish 8000pcs cartons/h.

A. Auto feeding part

1. Adopt belt type lead edge suction feeding, exact and reliable.

2. Adopt high quality electromagnetic clutch and electromagnetic braking system, can control the feeding part independently, easy to operate and reliable.

3. Paper pressing wheels is adjustable, suitable to paper thickness 2-8mm.

4. Linked with folding part, frequency control of speed, feeding speed 130m/min.

5. The front baffle and feeding belt can be adjusted left-right.

B. Folding gluing part

1.The host adopt frequency control of speed, non noise, adjust speed flexible and steadily.

2. Adopt imported high friction belt to convey the board, automatic folding.

3. Use stainless steel wheels to gelatinize, no failure, save glue.

4. Folding part equipped with paper correction device and creasing correction device.

C. Counting stacking part

1. Adopt digital control, simple operation, reliable action, can input data without stop, auto counting, exact outputting.

2. Use belt to convey the cartons, stacking tidily, stacking speed is 120m/min.

3. Has the rectification function, can adjust the error.

4. Counting and outputting adopt pneumatic method, move reliable, exact and fast.

5. Main component and belts adopt imported brand.

Maintenance: The parts of this machine use Chinese or international famous brand, stacking counting part has 4pcs belts are quick-wear part. Production qty is one million cartons. Other parts no need to change without wrong operation. Reasonable lubrication and maintenance is good for machine regular running and prolong the machine lifetime. Need regular detection of the machine, any problem can be solved in time.

Detection list as below:

|

Inspection item

|

Day

|

Wee

|

Month

|

Remark

|

|

Check all the control switch, limit, emergency stop and optoelectronic switch

|

☆ |

|

|

|

|

Check the air line and air pressure, especially oil and gas triplet

|

☆ |

|

|

|

|

Check if the bolt is loose or dropped

|

☆ |

|

|

|

|

Check the motor running status

|

☆ |

|

|

|

|

Check the chain and chain wheels on each part

|

☆ |

|

|

|

|

Check the belt abrasion condition and degree of tightness of each part

|

☆ |

|

|

|

|

Check each driving part bearings is hot or shake

|

☆ |

|

|

|

|

Check the hexagon shaft and belt wheels at the connection part between feeding and folding parts

|

☆ |

|

|

|

|

Check the air cylinder is normal or not

|

☆ |

|

|

|

|

Check the screw on each part is loose or not

|

☆ |

|

|

|

Lubrication

|

Lubrication parts

|

Engine oil |

Grease

|

Day

|

Week

|

| Air cylinder and guide bar |

☆ |

|

3times |

|

| Chain wheels and chain on each part |

|

☆ |

1time |

|

|

Guide bar and lead screw of pressing part

|

|

☆ |

|

1time |

|

Guide bar and lead screw of gluing parts

|

|

☆ |

|

1time |

| Lead screw of size adjusting part |

|

☆ |

|

1time |

|

Bearings of feeding and counting stacking part

|

|

☆ |

|

1time |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!