Carton Box Flexo Printing Slotting Machine Automatically Flexographic Printer

I. Feeding part

1. Machine combine and separation

1) Electric control machines with on-off alarm, continued between rang the bell warning, ensure that homework personnel security.

2) Transmission shaft with friction type clutch, avoid mistake and damage the machine.

3) Pneumatic type interlocking device.

4) Host motor start up protection device.

2. Lead edge send paper system

1) suction feeding, the blower 7.5 KW, can according to bend to ensure smooth feeding cardboard. (valve adjust air volume)

2) side baffle, pushing paper, back block box position adjusts by electric (digital control), baffle clearance before manual adjustment.

3) Skip feeding device. (according request, you can choose to delivery paper continuous or skip)

4) Counter for supplying paper, setting and displaying the production quantity.

5) Motorized and PLC control of feeder

3. Dust removal system

1) Air suction device on aspiration, draught absorption with brush, large cardboard on the printing of impurity clear, improve printing quality.

4. Send paper roller

1) external diameter ¢85 mm.

2) solid steel, parcel wear-resisting rubber, and make balance correction.

3) under feeding roller is with embossing hard chrome plating.

4) Feeding paper roller gap dial manual adjustment, adjusting range 0 ~ 12 mm.

5. Auto-return to zero device

1) send paper department, printing department, slotting of automatic electric zero.

general carton using automatic zero setting, make two pieces can adjust to the correct position, reduce the waste paper.

II. printing part

1) external diameter ¢393 mm( including plate is 405mm).

2) steel pipe surface grinding, hard chromium plating.

3) make balance correction and keep operation steadily.

4) ratchet fixed roll version axle.

5) Hung Groove on each printing drum, suitable for 10 mm hang bar.

the print plate loading and unloading, the pedal switch electric control and reversing.

2. Printing pressure roller

1) Steel pipe surface grinding with hard chrome

2) do balance correction and smooth operation.

printing pressure roller clearance dial manual adjustment, adjusting range 0--12 mm.

3. feeding roller upper and down

1) the top roller: external diameter ¢85 mm for solid steel, match three to deliver the paper ring.

2) the next roller: external diameter ¢155 mm for solid steel, the surface grinding, hard chromium plating.

to deliver the paper roller clearance dial manual adjustment, adjusting range 0 ~ 12 mm.

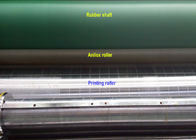

4. anilox roller

1) external diameter ¢215 mm. Steel pipe surface grinding, the suppression of anilox. Hard chromium plating.

2) Make balance correction and smooth operation.

3) the mesh number is 200-250 mesh for your choice.

4) cooperate with paper feeding system pneumatic type automatic lifting devices. (when feeding paper, anilox roll down to connect with printing plate, when stopped, please separate anilox roller and printing plate).

5) anilox roll with sphenoid clutch, ink, wash ink well when convenient and quick.

One unit is ceramic roll and doctor blade

5. Rubber roller

1) external diameter ¢190 mm.

2) steel tube surface package wear-resisting rubber, and do balance correction.

rubber high special grinding, the ink effect is good.

6. Phase adjustment

1) Phase Adjustment with planetary gear structure, the phase can be adjusted correctly 360 degree.

2) Electricity phase adjustment, digital show .and memory function, when stopped to clean the slab rubber, and when start again, it will be restored data as original set before stop.

3) Electric digital adjusts the horizontal position, and the distance can adjust 14 mm.

In the printing process, will automatic reset system after cleaning plate.

7. Ink system

1) pneumatic type diaphragm pumps, stable for ink, operate and maintain simple.

2) Ink filters, filtering impurities.

plastic ink tank.

8. Printing phase locked system

1) cylinder brake institutions.

when the machine or adjusting the phase separation and the brake institutions limit the rotation, maintain the original position gear up.

III. Die cutting part:

1. Die cutting upper roller

1) the diameter of roller is medium 378 mm, surface grinding, plating hard burger, move smoothly, including pads in the 398 mm. (Taiwan super 10 mm thick rubber resistance)

2) has speed limit compensation device.

3) rubber roller to move transversely 40 mm, prolong the service life of the rubber.

automatic repair device, improve pads utilization rate, can repair the three to four times.

2. Die cutting down roller

1) the diameter of roller is medium 360 mm, surface grinding, plating hard-chrome.

2) equipped with lift roller, no cardboard, mould roller to be automatic drop, reduce wear rubber roller.

3. Phase adjust system

1) the planet type gear structure.

the phase PLC and LCD control and electric digital 360 ° adjustment. (operation, stop all can adjust)

IV. Main technology parameter

| Model |

SMYS-QY-2000 |

SMYS-QY-2200 |

SMYS-QY-2600 |

SMYS-QY-2800 |

SMYS-QY-3000 |

| Inboard width (mm) |

2000 |

2200 |

2600 |

2800 |

3000 |

| Max. speed (pcs/min) |

120 |

120 |

120 |

120 |

120 |

| Max. paper size (mm) |

910x1800 |

910x2000 |

1270x2400 |

1270x2600 |

1270x2800 |

| Min. paper size (mm) |

280x600 |

280x600 |

350x700 |

350x700 |

350x700 |

| Max.printing area (mm2) |

840x1640 |

840x1840 |

1200x2200 |

1200x2400 |

1200x2600 |

| Printing precision (mm) |

±0.75 |

±0.75 |

±0.75 |

±0.75 |

±0.75 |

| Printing plank thickness (mm) |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

| Paperboard thickness (mm) |

3~11 |

3~11 |

3~11 |

3~11 |

3~11 |

| Min. grooving space (mm) |

190x50x190x50 |

190x50x190x50 |

190x50x190x50 |

190x50x190x50 |

190x50x190x50 |

| Max. slot depth (mm) |

210 |

210 |

300 |

300 |

300 |

| Total power (kw) |

20 |

20 |

22 |

22 |

22.5 |

| Dimensions (mm) |

6500x3230x2000 |

6500x3430x2000 |

7500x4000x2400 |

7500x4500x2400 |

7500x5000x2400 |

| Weight (T) |

16 |

18 |

19 |

22 |

25 |

Motor and electric part list

| Name |

From |

Model |

Pcs |

| Main motor |

Hebei |

22Kw converter motor |

1pcs |

| Bearing |

Harbin |

All |

|

| Electric |

Schneider |

All |

|

| Clutch |

Xianyang |

All |

|

| Air cylinder |

Zhejiang |

All |

|

| Diaphragm pump |

Wuhan |

All |

|

| |

Spare parts |

Function |

Brand |

Note. |

| 1 |

Lead edge feeder paper system |

Three row wheel |

Shandong |

|

| 2 |

Frequency transformer |

Main motor 18kw

|

Ori |

|

| 3 |

Check component |

|

Schneider |

|

| 4 |

Electrical components |

|

Schneider |

|

| 5 |

PLC |

|

Schneider |

|

| 6 |

Coder |

|

Zhejiang xinling |

|

| 7 |

Touch screen |

Main screen seven inches |

Delta |

|

| 8 |

Phase control instrument |

|

Shanghai |

|

| 9 |

Bottom |

|

Schneider |

|

| 10 |

Main motor |

15kw |

Hengshui Mengniu |

Converter motor |

| 11 |

Fan |

7.5kw |

Shandong |

|

| 12 |

Gear reducer motor |

0.18kw

0.37kw

|

Zhejiang |

Phase repair side baffle |

| 13 |

Ink motor |

400w |

Tiawan Dongte |

|

| 14 |

Split motor |

750W |

Taiwan Dongte |

|

| 15 |

Main machine wall |

Thickness 50mm |

Precision cast iron |

Finishing of Mitsubishi Five-sided Machining Center in Japan |

| 16 |

Drive gear |

Thickness 60mm |

40Cr |

Tooth picking and high frequency processing |

| 17 |

Printing roller |

Φ390.6mm |

|

45 # steel coil welded, computer dynamic balance correction, hard chromium plating after grinding |

| 18 |

Steel mesh roll |

Φ219mm |

Dalian Tengda |

Dynamic balance correction, double disk and double welding |

| 19 |

Rubber roller |

Φ210mm |

Guangzhou |

Dynamic balance correction, double disk and double welding |

| 20 |

Bottom printing roll |

Φ154.3mm |

45#seamless steel tube |

Dynamic balance correction, hard chromium plating |

| 22 |

Die cutting roller |

Up roller Φ389

Down roller Φ360

|

Precision cast steel |

Dynamic balance correction, hard chromium plating |

| 23 |

Bearing |

|

Wanxiang Brand |

|

| 24 |

pneumatic component |

|

Zhejiang Tianao |

|

| 25 |

Pneumatic single diaphragm pump |

|

Wuhan Jinchangjiang |

|

| 26 |

Keyless connection ring |

|

Xianyang |

|

| 27 |

free wheel device |

|

Xianyang |

|

| 29 |

Superior glue |

Wide 250mm |

German diet |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!