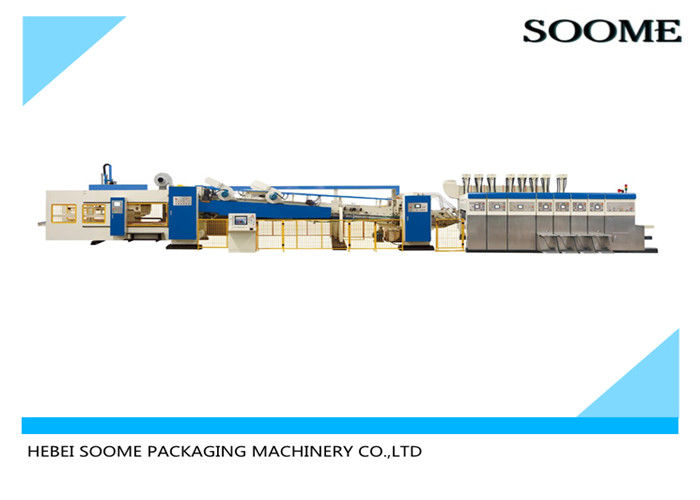

FFG Inline Automatic Corrugation Machine Printer Die Cutter Slotter Stacker Strapper

Main technical parameters:

| Item. |

Unit |

Parameters |

| Inner width of wallboard |

mm |

3000 |

| Max. feeder paper area(Continuous) |

mm |

1200X2800 |

| Max. feeder paper area(Skip) |

mm |

1280X2800 |

| Max. efficient printing |

mm |

1200X2650 |

| Min. machining size |

mm |

330X550 |

| Printing plate thickness |

mm |

7.2 |

| Max.machine speed |

sheets/min |

260 |

| Work speed |

sheets/min |

120-200 |

| Main motor power |

KW |

22 |

| Total power |

KW |

35 |

| Color accuracy |

mm |

±0.5 |

| Slotting/die cutting accuracy |

mm |

±1.5 |

| Outline dimension |

mm |

Printing machine L8000*W5100*H2300 |

| Feeder paper accuracy(mm) |

mm |

±1.0 |

Machine performance:

1 .Human-computer interface,full-touch screen operation.Computer controlled storage of common orders,It is faster to change orders and more convenient to operate.

2 . All electrical appliances and electronic components are made up of internationally renowned brands

3 . All transmission rollers are made of high quality steel, hard chromium plated and ground.

4 . Wallboard is 50 thick and high quality cast iron, which is processed by CNC machining center after internal stress removal.

5 . Spraying process: Before spraying, parts can be rusted-phosphating-spraying-baking paint, which can make the paint rust-proof, hard surface and more durable.

6 . The whole machine is equipped with alarm bell; keep ringing alarm when walking to ensure the safety of operators.

7 . Each unit is equipped with emergency stop switch, which can stop the movement of each unit internally to ensure the safety of internal operators.

8 . Spray lubrication double oil pump automatic circulation system to maintain oil level balance.

9 . The number of orders that can be stored in a computer control system can reach 999. (the main control computer operates on the slotted side)

10 . The operating side of the main engine is a double shell,the inner closed tank is made of 6 thick and high quality iron plates,Welding of 2 thick and high quality iron plates for outer layer adjustment,two-layer covers can effectively reduce mechanical noise.The clearance adjustment mechanism of the two-stage worm gear box can make the printing accuracy,The paper feeding clearance is adjusted more accurately and quickly.

All paper feeding pressure, printing pressure, slotting pressure and die cutting pressure are operated by computer touch screen.

No need to enter the unit to adjust, save a lot of adjustment time and labor costs, improve production efficiency.

Main motor,Feeder paper fan,Phase motor adopt converter motor,Frequency converter control,

Energy saving, stable start-up.

1200 Type folder gluing packing line

Mechanical properties :

1. The average speed of the machine is 8000-12000 per hour.Fast speed,improve production efficiency greatly.

2. Automatic gluing,automatic folding,automatic correction, automatic counting and automatic stacking,Only two people can complete the whole process.

3. The folded beams are conveyed by elastic roller and suction belt.Accurate delivery.Man-machine correction and electric adjustment of two folded beams, with pre-pressing, shaping and correction devices, can make cartons fold to eliminate large and small openings and reduce waste rate.

4. It has the function of differential deviation rectification and adjustment, eliminating the scissors edge.

5. The automatic patting device, paper connection, stacking and discharging of the whole paper discharging part are precisely controlled by the servo system, and the circulation speed is fast. It can move left and right according to the folding size of cardboard.

6. Up gluing part,pre-pressure part have paper-receiving push-button,When the paper feed button is pressed,slotting machine stop feeder paper,prevent waste of cardboard.

7. In the folding beam automatic tracking slotting machine, the cutter moves horizontally, which is convenient to adjust and can minimize the size of the carton.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!